With the strengthening of design and manufacturing of molds and the realization of new mold technology, more and more attention has been paid to mold quality. No matter from which aspect, many things in modern life have been gradually replaced by plastic, no matter where The products produced by local plastic mold factories have attracted great attention to quality problems. Any quality problems may cause product cracking, sticking, deformation, flashing, and size problems.

The product quality of the plastic mold factory includes the following aspects:.

⑴Service life: Under the premise of ensuring product quality, the number of work cycles that the mold can complete or the number of parts produced.

⑵Product quality: product size stability, compliance, product surface finish, product material utilization rate, etc.

⑶ The use and maintenance of the mold: Whether it is the most convenient to use, easy to demold, and the production auxiliary time as short as possible.

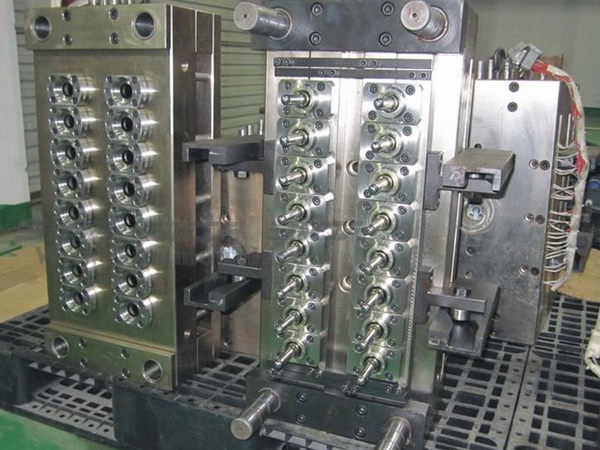

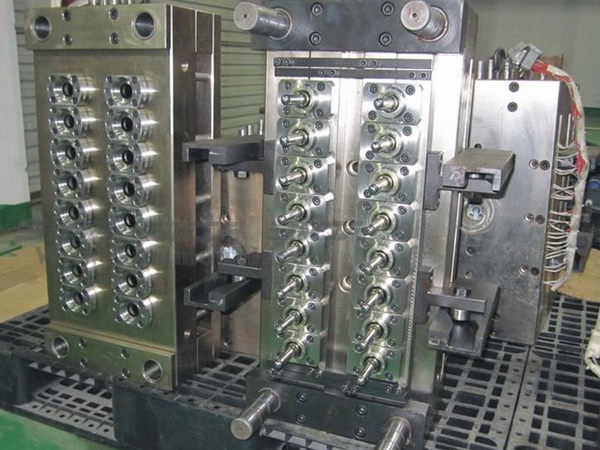

The basic way to improve the quality of the plastic mold factory: The design of the mold is the most important step to improve the quality of the mold. Many factors need to be considered, including the selection of mold materials, the usability and safety of the mold structure, and the manufacturing process of the plastic mold factory. It is also an important part to ensure the quality of the mold. The processing method and processing accuracy in the mold manufacturing process will also affect the service life of the mold. The surface of the main injection mold forming parts of the mold is strengthened to improve the surface wear resistance of the mold parts. To better improve the quality of the mold, the correct use and maintenance of the mold is also a major factor in improving the quality of the mold. For example, the installation and debugging method of the mold should be appropriate. In the case of hot runners, the power supply wiring should be correct and the cooling water circuit should be satisfied. Design requirements, the parameters of injection molding machines, die-casting machines, and presses in the production of molds must meet the design requirements and so on.

In the packaging industry, the injection molding process has attracted more and more attention. The reason is that people use multi-layer molds. This is an advancement in hot runner technology. Through the use of thin-wall injection molding technology, the cost of raw materials can be saved. Other special processes For example, stamping marking method and multi-component technology have also played a positive role in reducing process steps, increasing output and improving efficiency.

Plastic packaging materials, especially in the food industry, have made a great contribution to improving our living standards today due to their light weight and good durability. In addition, products produced by large-scale industrialization should be distributed all over the world. If there is no packaging material, it is also unimaginable. So on the whole, in the past few years, the entire plastic packaging market, mainly deep-drawn packaging plastic film, has grown rapidly. Among them, injection molding packaging materials, Such as packaging boxes or cups, are in the rising stage and gradually replace thermoformed packaging materials.

From this point of view, the following trends can be inferred:

Higher material costs and additional emission fees have prompted people to use light-weight packaging materials.

The requirements for the performance of packaging materials are getting higher and higher. Today's good packaging materials should have many functions, such as good writeability, prevention of accidental opening and accurate portion distribution.

Due to the globalization of packaging material processing and sales, the output of packaging materials has increased rapidly. As a result, multi-layer cavity molds have been widely used.

This development not only has an impact on production, but also affects the product itself. Although the increase in productivity and the reduction in product weight have always been priority factors, there will still be other issues, such as consumer protection and wordmarks. Wait.

For the requirements of comfort and consumer protection, it can be achieved by a corresponding safety lock. In order to increase the strength of the edge part, fastening ribs can be added. This measure can improve the overall performance of the material. If it is thermoforming If the material is used, it is impossible to achieve this effect. In addition, polypropylene with good transparency can exert its optical properties, and the printing process can be omitted by stamping.